Rubber Goods

Products made from rubber are a vital part of everyday life. This super-stretchy material finds its way into tens of thousands of different products—everything from rubber stamps and waterproof shoes to surfing wetsuits, swimming caps, and dishwasher hoses.

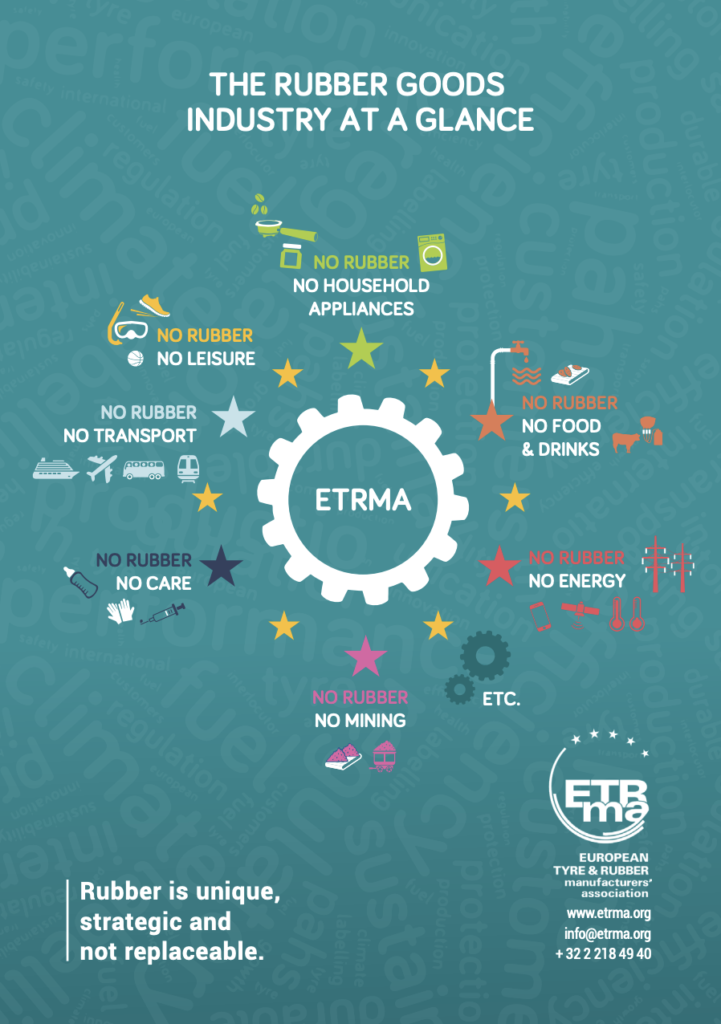

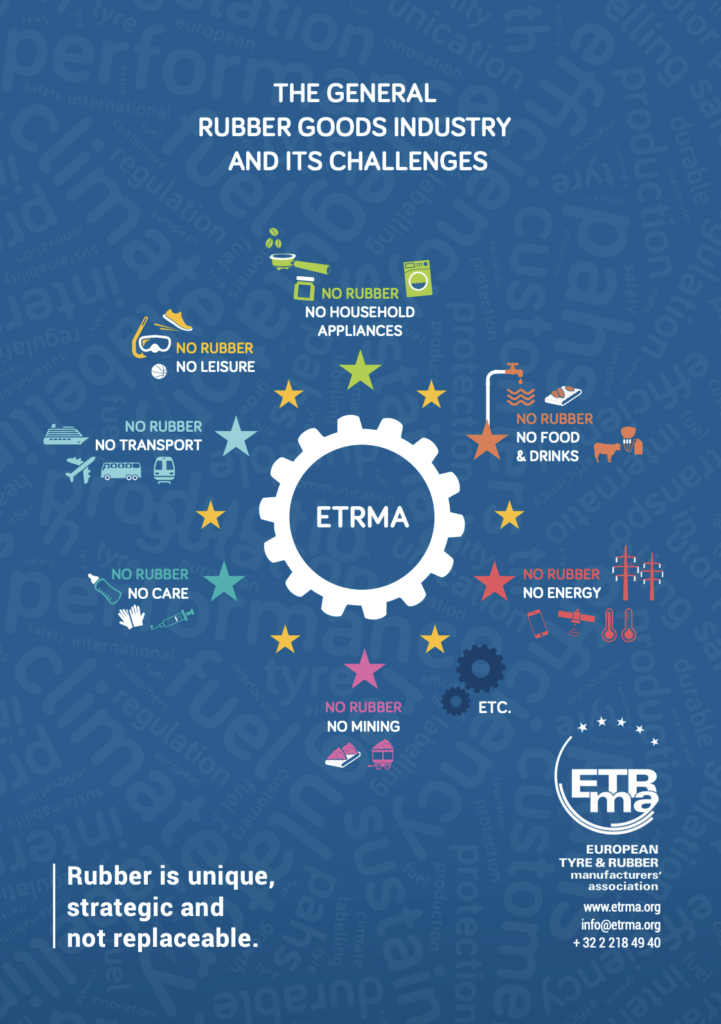

From aerospace to aeronautic, from the depth of the seas to the depth of the earth, from agriculture to household appliances, rubber products are everywhere and serve all kinds of industries, whose products could not function without the often-small technical rubber products. Applications are so broad that comparatively few people are aware how dependent we are on this remarkable product.

Read further to find out more about the Rubber industry and it’s challenges

Supporting SMEs

The Rubber sector is characterised by:

Small and Medium Enterprises

In Europe, there are more than 6000 companies producing rubber goods. 98% of them are SMEs who operate in a highly integrated value chain to respond to the very specific and often niche needs of their customers.

High investments in advanced technologies

Investments are made to keep up with evermore demanding downstream sectors. These, combined with the characteristics of rubber, make such products strategic, unique and not replaceable.

Rubber and automotive

The automotive sector accounts for 65% of the production of general rubber goods. Beyond tyres, wiper blades, seals, air and radiator hoses and seatbelts list rubber as their main components. Rubber is resistant to several chemicals used in a car and can withstand the heat and cold. Rubber is also used to make gaskets used in cars, which help create a seal so there is no leak when fluids are flowing through junction areas in a pipe or a hose. Rubber is also used to cover electrical wires and to create shields for electrical parts and pieces in a car.

Rubber and every-day life

Household appliances, industrial applications and the energy/offshore industry account for another 30% of the market.

There are also hundreds of uses for rubber in the construction industry and in the leisure and sports equipment. Food contact articles are also a beneficiary of rubber: it is used in teats, toys and rubber seals which form essential parts of supply systems for drinking water.

Science Network

To support the competitivenss of general rubber goods manufacturers, ETRMA supported the creation of the European Research & Rubber Laboratories (ERRLAB), an informal network of laboratories for research and testing in rubber applications. Its objective is to share resources and expertise in order to provide a complete technical service to the European rubber manufacturing industry, with a focus on small and medium enterprises, in the field of Environment, Health and Safety studies, Research & Development, testing and certification. It was established by France, Germany and Italy benchmark rubber laboratories (LRCCP, DIK, CERISIE respectively), pulling together the expertise of more than 100 doctors, engineers and technicians highly rubber specialised.

To support the competitivenss of general rubber goods manufacturers, ETRMA supported the creation of the European Research & Rubber Laboratories (ERRLAB), an informal network of laboratories for research and testing in rubber applications. Its objective is to share resources and expertise in order to provide a complete technical service to the European rubber manufacturing industry, with a focus on small and medium enterprises, in the field of Environment, Health and Safety studies, Research & Development, testing and certification. It was established by France, Germany and Italy benchmark rubber laboratories (LRCCP, DIK, CERISIE respectively), pulling together the expertise of more than 100 doctors, engineers and technicians highly rubber specialised.